CALL US: 1-888-766-6610

Electrical Contactors: Exploring Various Types and Their Applications

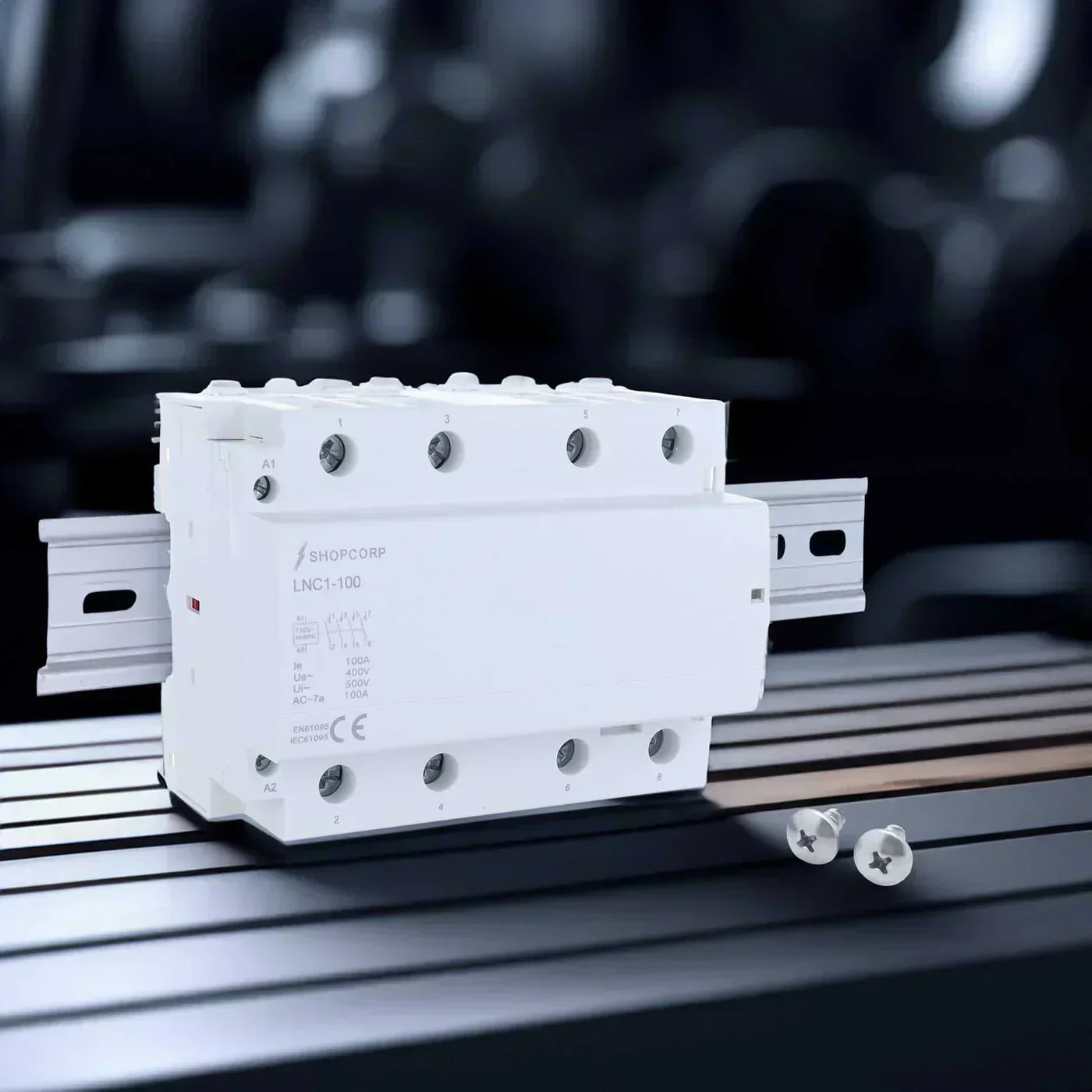

In the realm of electrical systems, the electrical contactor stands out as a fundamental component, ensuring seamless control over electrical circuits. These devices are engineered to handle high current loads, making them indispensable in both industrial and commercial settings. This article delves into the diverse types of electrical contactors, shedding light on their unique features and applications.

Understanding Electrical Contactors

An electrical contactor is an electromechanical switch used to control the flow of electricity in a circuit. Unlike manual switches, contactors are designed for high-voltage applications and can be operated remotely, providing enhanced safety and convenience. They are commonly employed to control electric motors, lighting systems, HVAC units, and other heavy-duty equipment.

Electrical Contactors Offered by Contactor Depot

At Contactor Depot, we provide a comprehensive range of high-quality electrical contactors tailored to meet diverse application needs. Our product categories include:

Motor Control Contactors

Designed to manage the operation of electric motors, these contactors ensure efficient and reliable motor performance. They are suitable for various motor-driven applications, offering features like high durability and optimal performance under heavy loads.

Lighting Contactors

Our lighting contactors are ideal for controlling lighting circuits in commercial and industrial environments. They support various lighting loads, including tungsten, mercury, LED, and sodium lights, ensuring silent and efficient operation.

HVAC Contactors

Specifically engineered for heating, ventilation, and air conditioning systems, these contactors provide reliable switching for compressors, fans, and other HVAC components. They are built to withstand the demanding conditions of HVAC applications, ensuring longevity and consistent performance.

Selecting the Right Electrical Contactor

When choosing an electrical contactor, consider the following factors:

Current and Voltage Ratings

Ensure the contactor can handle the specific electrical load of your application.

Type of Load

Different contactors are designed for specific load types, such as motors or lighting systems.

Environmental Conditions

Consider factors like temperature, humidity, and exposure to dust or chemicals, which may affect the contactor's performance.

Size and Mounting

Ensure the contactor fits within your system's spatial constraints and is compatible with existing mounting configurations.

Common Issues with Electrical Contactors and Troubleshooting Tips

Electrical contactors are vital for controlling power in various applications, but they can encounter issues that affect system performance. Understanding common problems and their solutions can help maintain system reliability.

Common Issues:

Contact Wear and Pitting

Over time, the contact points can degrade due to arcing, leading to increased resistance and potential overheating.

Coil Failures

Voltage fluctuations or prolonged operation can cause the coil to overheat or short-circuit, resulting in malfunction.

Dust and Debris Accumulation

Contaminants can interfere with the contactor's operation, causing poor connectivity or mechanical failure.

Mechanical Wear

Frequent cycling can lead to wear in moving parts, affecting the contactor's ability to engage or disengage properly.

Troubleshooting Tips

Regular Inspection

Periodically check contacts for signs of wear or pitting. If significant degradation is observed, consider replacing the contacts or the entire contactor.

Voltage Verification

Ensure that the coil voltage matches the system specifications. Use a multimeter to check for voltage inconsistencies.

Cleaning

Keep the contactor and its environment clean. Use appropriate cleaning methods to remove dust and debris without damaging components.

Lubrication

Apply suitable lubricants to moving parts as recommended by the manufacturer to reduce mechanical wear.

Implementing these practices can enhance the longevity and reliability of electrical contactors in your systems.

Best Practices for Electrical Contactor Maintenance

Proper maintenance of electrical contactors is essential to ensure the safety and efficiency of electrical systems. Adhering to best practices can prevent unexpected failures and extend the lifespan of these components.

Maintenance Guidelines:

Routine Visual Inspections

Tightening Connections

Testing and Calibration

Environmental Control

Documentation and Record-Keeping

Understanding the various types of electrical contactors and their applications is crucial for maintaining efficient and safe electrical systems. By selecting the appropriate contactor from Contactor Depot's extensive range, you can ensure optimal performance and longevity of your electrical installations.